While efficiency is paramount, the robustness of an SMT assembly line against disruptions is equally critical for sustained high-volume production. Modern electronics manufacturing requires not just speed but unwavering reliability, where the entire SMT assembly system functions cohesively even under pressure. Material management and logistics form the bedrock of this resilience.

Precision Warehousing: Mitigating Supply Chain Vulnerabilities

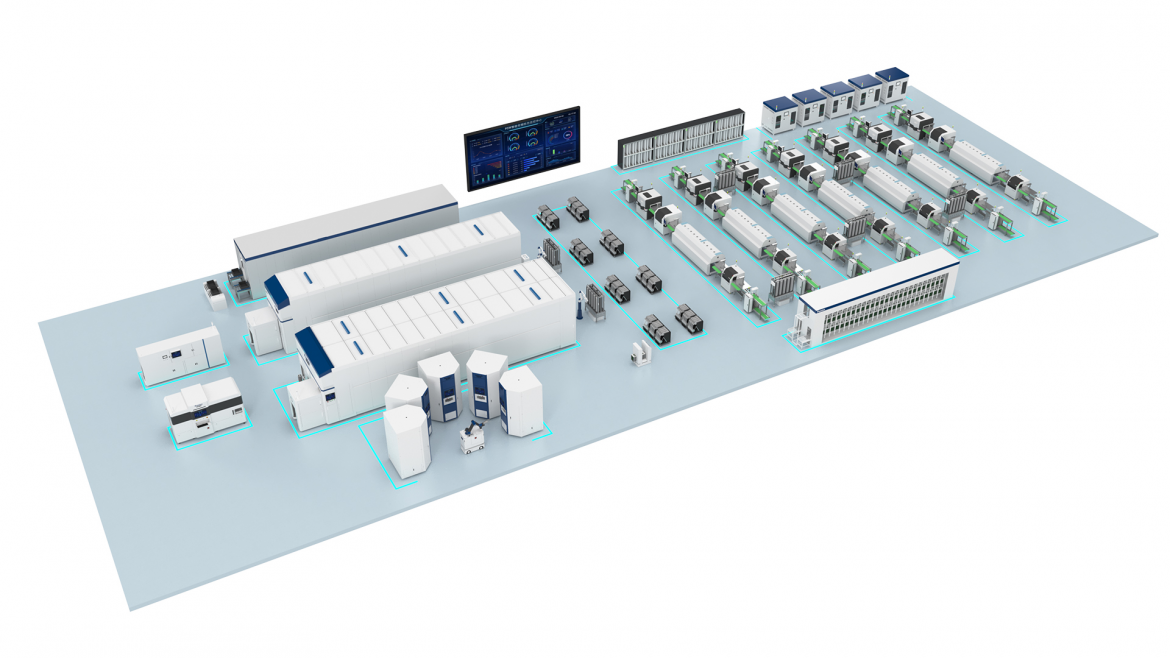

The vulnerability of an SMT assembly line often lies in component availability. Manual inventory errors or delays in retrieving specific reels can halt production unexpectedly. Solutions like PassionIOT’s automated warehousing address this by providing high-precision storage and retrieval. Features such as automation, large capacity, and “Smart Access” ensure components are accurately catalogued and instantly accessible. This precision minimizes the risk of line stoppages due to missing or misidentified parts, directly bolstering the uptime and predictability of the SMT assembly system. Consistent material availability becomes a shield against supply chain hiccups.

Agile Logistics: Ensuring Continuous Material Flow

Material transport bottlenecks can cripple throughput. Relying on manual handling introduces variability and potential for delays. PassionIOT‘s “Directed Logistics” utilizing AGVs creates an unmanned, intelligent transport layer. AGVs autonomously manage the flow of materials from warehouse storage directly to the SMT assembly line feeders and handle online distribution points. This system operates independently of shift changes or labor shortages, ensuring a continuous, just-in-time supply. The resilience of this automated logistics network is vital for maintaining the relentless pace required by a high-speed SMT assembly system, especially during peak demand or extended production runs.

Conclusion

Shifting the lens from pure efficiency to operational resilience reveals the true strength of a well-orchestrated SMT production ecosystem. By integrating high-precision warehousing with autonomous, intelligent logistics, manufacturers fortify their SMT assembly lines against unforeseen interruptions. This infrastructure acts as a bulwark, weathering operational storms and ensuring the SMT assembly system functions not just quickly, but with unwavering continuity. The result is a production floor characterized not merely by speed, but by enduring, dependable output – the foundation for meeting stringent delivery commitments in a demanding market.