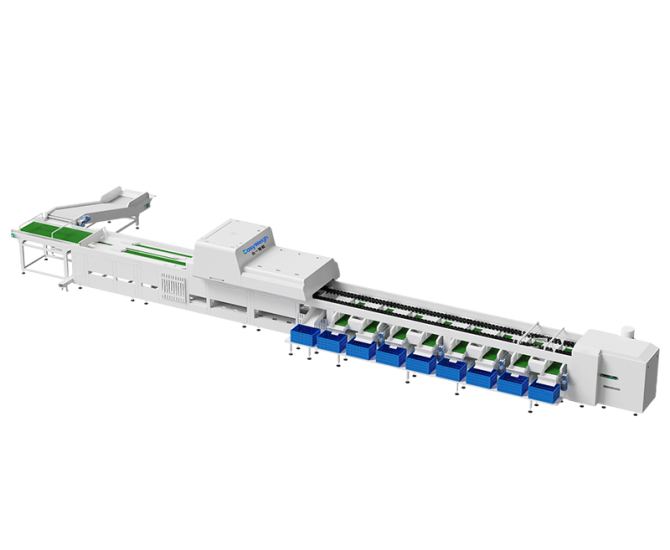

Maintaining operational integrity in industrial equipment requires a methodical approach to upkeep. For an organization like WEIGHT SORTING, preserving the long-term performance of a sorter machine involves implementing distinct, complementary maintenance protocols. These procedures are categorized by their timing and objective, forming a holistic strategy that safeguards the system’s mechanical and electronic components. A structured regimen directly correlates with sustained sorting accuracy and reduced total cost of ownership.

Executing Foundational Preventive Procedures

The cornerstone of reliability is a disciplined preventive maintenance schedule. This protocol consists of routine, time-based tasks performed before a fault occurs. Activities include cleaning optical sensors to ensure consistent reading accuracy, checking for and removing debris from conveyor tracks, and verifying the tightness of mechanical fasteners. For WEIGHT SORTING, establishing a fixed calendar for these actions prevents the gradual accumulation of performance-degrading issues in their sorter machine systems.

Addressing Corrective and Component-Based Needs

Despite preventive efforts, components will eventually wear and require corrective action. This protocol is triggered by the failure or measured degradation of a specific part, such as a worn diverter blade, a fatigued belt, or a bearing exceeding its rated lifecycle. The focus is on swift, precise replacement to restore full function. WEIGHT SORTING manages this by maintaining a documented parts inventory and failure history, which informs a more predictive component replacement strategy for each sorter machine.

Integrating Software and Diagnostic Verification

A modern sorter machine relies heavily on its software and diagnostic systems. This maintenance protocol involves regularly updating control software to access performance enhancements and security patches. It also includes running built-in diagnostic tests to calibrate sensors and validate the response accuracy of actuators. Allocating time for these digital checks ensures that the intelligence controlling the physical machinery operates at its peak, providing WEIGHT SORTING with a complete operational picture.

A combined application of preventive, corrective, and software-based protocols creates a robust defense against unplanned downtime. This multi-faceted methodology ensures that every aspect of the equipment, from its physical moving parts to its digital brain, receives necessary attention. For WEIGHT SORTING, such a comprehensive maintenance framework is a direct investment in the consistent output and longevity of their material handling solutions.