Die casting has transformed the landscape of metal manufacturing, enabling the production of intricate and precise components that are essential in various industries. This article explores how high-pressure die casting works, its advantages, and why selecting a reliable die casting manufacturer like Dingmetal can significantly enhance your production capabilities.

The Fundamentals of Die Casting

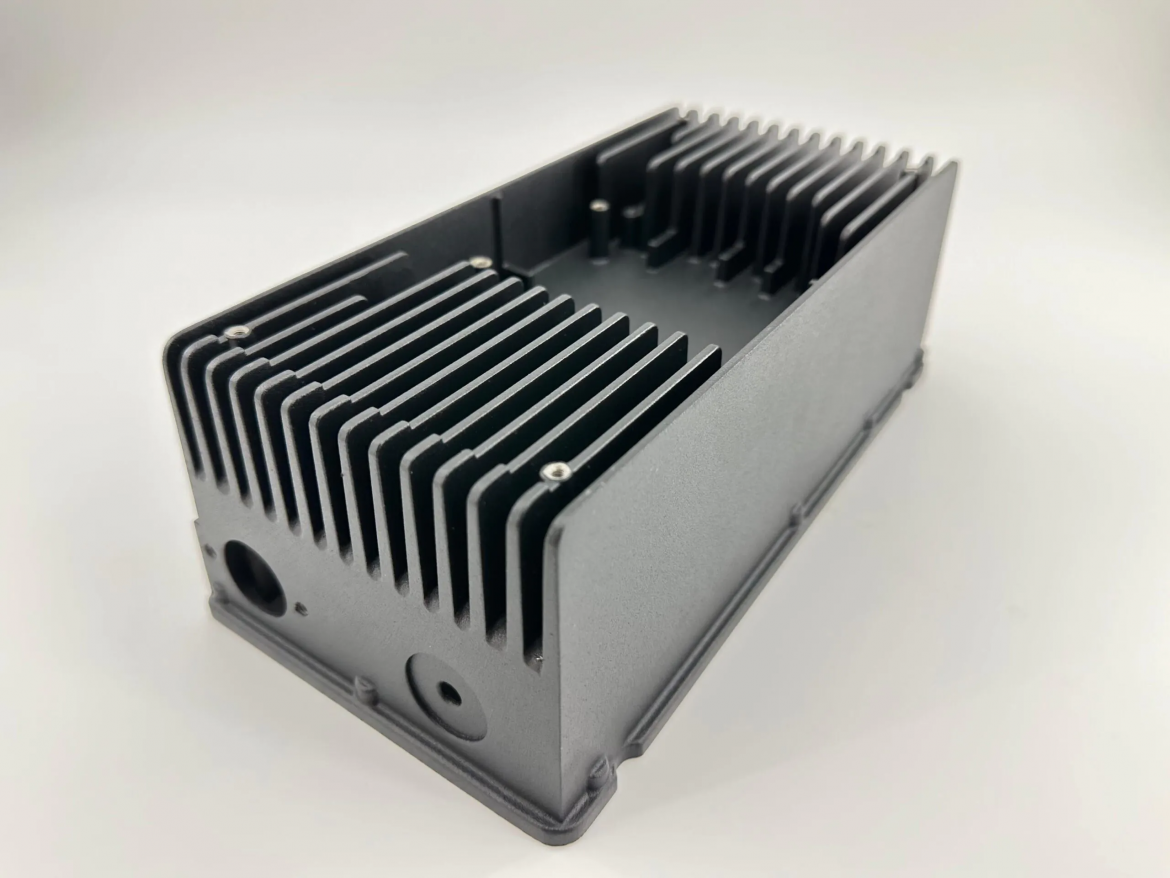

At its core, die casting is a metal casting process that involves injecting molten metal into molds called dies under high pressure. This method enables manufacturers to create complex geometries with high dimensional accuracy and smooth surface finishes. Unlike traditional casting methods where gravity plays a major role, die casting ensures that the metal fills the mold completely, minimizing defects and enhancing product quality.

High-pressure die casting is particularly advantageous for high-volume production runs, typically exceeding 1,000 units. The efficiency of this process lies in its ability to reduce per-unit costs by offsetting the initial investment in tooling and Non-Recurring Engineering (NRE) costs. For businesses looking to mass-produce components without sacrificing quality, partnering with a seasoned die cast supplier is crucial for leveraging these benefits effectively.

The Die Casting Process Explained

The die casting process can be broken down into several key steps. Initially, a carefully selected metal alloy, often aluminum, magnesium, or zinc, is heated until it reaches a molten state. The molten metal is then injected into a preheated die at high pressure, typically ranging from 1,000 to 30,000 psi. This pressure forces the metal into every contour of the mold, ensuring that even the most intricate designs are accurately reproduced.

Once the metal cools and solidifies, the die opens, and the finished parts are ejected. Importantly, the precision of the die casting process means that many components require little to no post-processing or machining, streamlining the production cycle. Companies seeking high-quality components with tight tolerances can benefit tremendously from the specialized services of a die casting manufacturer like Dingmetal.

Benefits of High-Pressure Die Casting

High-pressure die casting provides several advantages that make it an attractive option for production. One of the most significant benefits is the consistency and quality of the parts produced. With advanced machinery and skilled operators, a die casting supplier can ensure that every piece meets stringent quality standards, reducing the risk of defects and rework.

Moreover, high-pressure die casting allows for rapid production cycles, which is paramount for industries that demand quick turnarounds. The process can produce thousands of parts in a matter of days, significantly accelerating time to market. Additionally, the utility of this method extends beyond just aluminum; it can accommodate a variety of alloys, tailoring solutions to meet specific industry needs.

Choosing a reputable die casting manufacturer like Dingmetal offers clients not only high-quality components but also collaborative expertise throughout the manufacturing process. Their experience in OEM and ODM die casting services means that customers receive tailored solutions that align perfectly with their design requirements.

Choosing the Right Partner for Your Die Casting Needs

Understanding how high-pressure die casting works and its numerous advantages positions businesses to make informed decisions regarding their manufacturing processes. Selecting a reliable die cast supplier is crucial for ensuring that each component produced not only meets quality expectations but also enhances overall operational efficiency.

Dingmetal stands out as an exceptional partner for your die casting needs, boasting advanced manufacturing capabilities that deliver precisely engineered parts with intricate geometries and tight tolerances. By choosing Dingmetal, companies can leverage their expertise in the die casting process to accelerate production timelines and optimize product performance.